How 3D Crystal Engraving Works: Laser Process, 2D vs. 3D, Curve Engraving & Tips

- 3D Crystal

.jpg/v1/fill/w_320,h_320/file.jpg)

- Aug 5, 2025

- 4 min read

Introduction

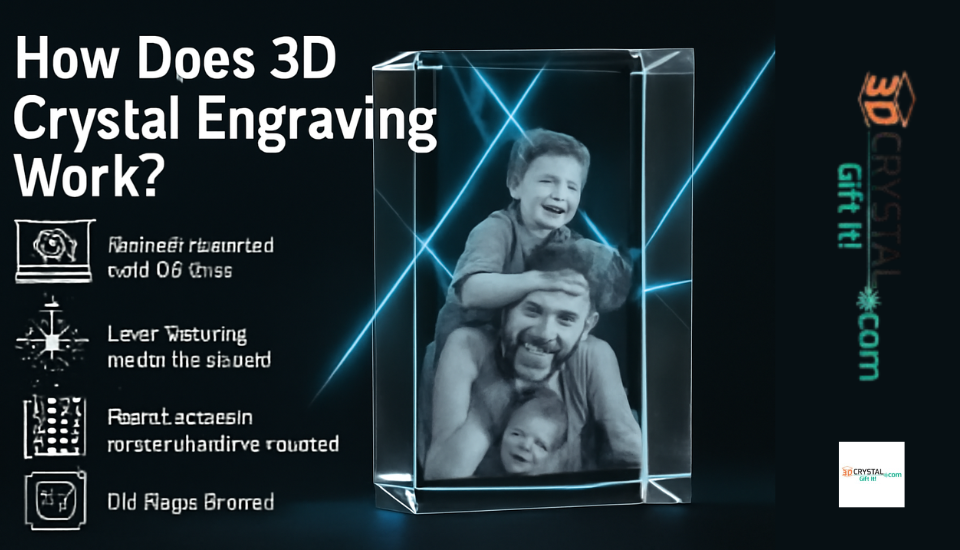

Turning a simple photograph into a three-dimensional crystal masterpiece may seem like magic. In reality, 3D crystal engraving harnesses precision laser technology and optical science to “print” tiny fractures inside glass or crystal blocks or 3d crystal rectangle wide blocks , resulting in lifelike depth and detail. Whether you’re a gift-shop owner, a tech enthusiast, or simply a curious beginner, this guide will demystify the entire process—from basic terminology to advanced techniques like curve engraving.

In addition to exploring how 3D crystal engraving works, you can dive deeper into the broader world of three-dimensional imaging in our companion article, What is a 3D Glass Picture? Complete Guide to 3D Images & Crystal Engraving?. That post covers everything from stereoscopic 3D glasses and laser-engraved crystal blocks to real-world applications, helping you understand both the technology and its many uses.

1. What Is 3D Crystal Engraving?

3D crystal engraving, also called subsurface laser engraving (SSLE), uses a focused infrared or green laser to create micro-fractures within a transparent medium. Each fracture point reflects light, and thousands of these points together form detailed 3D images visible from any angle—no glasses required.

Key Benefits

Permanent and Fade-Free: Unlike surface etching, the interior engraving won’t wear off.

High Definition: Laser can produce millions of dots per crystal, yielding crisp detail.

360° Viewing: Turn the block to see all sides of your image.

2. How Is 3D Engraving Done? The Laser Process Explained

Understanding each step helps you appreciate the precision involved.

2.1 Image Preparation

3D Conversion: A 2D photograph is converted into a 3D point-cloud or mesh file via specialized software.

Depth Mapping: The software assigns depth values to different parts of the image (foreground vs. background).

File Optimization: Points are sampled to balance resolution and engraving time.

2.2 Crystal Selection

K9 vs. K5 Crystal: K9 offers superior clarity and fewer internal stresses; K5 is more budget-friendly but may feature minor inclusions.

Acrylic Alternatives: Less expensive but lower clarity and prone to surface damage.

2.3 Laser Engraving

Laser Type: Commonly green (532 nm) due to optimal absorption in glass.

Focus Point: Each laser pulse creates a minuscule plasma explosion (~30–80 µm wide).

Point-by-Point Scanning: Computer-numerical-control (CNC) moves the laser focus in X, Y, and Z axes to “draw” the 3D shape.

Dot Density: Higher dots-per-second rates (up to 4,500,000 dots) yield finer details but increase processing time(see the generated image above).

2.4 Finishing Touches

Surface Polishing: Ensures no external blemishes distract from the internal image.

LED Base (Optional): Illuminates the crystal to accentuate the engraving.

3. 2D vs. 3D Engraving: What’s the Difference?

Feature | 2D Engraving | 3D Engraving (SSLE) |

Depth Representation | Flat, single-plane image | True three-dimensional volume |

Viewing Angle | Best viewed straight on | Viewable from any angle |

Detail Level | High for lines and text | High for volume but slower |

Production Speed | Faster (surface etch only) | Slower (point-by-point inside) |

Durability | Surface can scratch/wear | Internal so immune to surface damage |

4. Does Every 3D Crystal Picture Use Laser Engraving?

Yes. All authentic 3D crystal pictures rely on laser engraving beneath the surface. No chemical etching or press-molding process can achieve the same combination of detail, depth, and permanence.

5. How Do They Put Images Inside Crystal?

By precisely focusing laser pulses at predetermined coordinates within the block, each pulse vaporizes a microscopic spot, leaving behind a tiny bubble or fracture that forms the image’s “voxels.” As the laser moves in three dimensions, a volumetric representation of the image is constructed entirely inside the crystal.

6. What Is 3D Curve Engraving?

Traditional SSLE engraves in straight-line layers. 3D curve engraving modifies the laser’s X-Y path to follow curved paths or contours, enabling:

Organic Shapes: Engraving along a subject’s anatomy (e.g., a model’s silhouette).

Artistic Effects: Smooth curves that enhance depth perception.

Custom Surfaces: Non-flat block geometries, like cylinders or spheres.

7. Can You Laser Engrave Crystal Glass?

Absolutely. High-power, short-pulse lasers (picosecond or femtosecond) can engrave both standard glass and high-grade optical crystals. Key considerations include:

Laser Wavelength: Green lasers deliver optimal energy absorption in silica.

Pulse Duration: Shorter pulses minimize thermal damage.

Focus Accuracy: Sub-micron precision stages ensure dot placement accuracy.

8. Common Use Cases & Real-World Examples

Personal Keepsakes: Wedding portraits, family photos in crystal, and anniversary gifts.

Corporate Awards: Executive recognitions with company logos and 3D text.

Medical Models: Patient-specific anatomical structures for surgical planning.

Industrial Prototypes: 3D scans of machine parts embedded for quality control archives.

9. Tips for Best Results

Use High-Resolution Originals: 600 DPI or higher to capture fine details.

High Contrast Images: Clear distinction between subject and background.

Centralized Composition: Keep important elements near the block’s center to avoid edge distortion.

Professional File Preparation: Employ a lab or service with optimized SSLE software to balance dot density and processing time.

10. Troubleshooting & FAQs

Q: Why does my image look grainy?A: Likely low dot density—request higher point-per-second settings or increase image contrast.

Q: Can I engrave colored images?A: Standard SSLE yields monochrome (white) points. Some advanced systems embed colored pigments in fractures, but these are specialty services.

Q: How long does engraving take?A: Depends on size and resolution—small (5×5 cm) blocks at medium detail take 20–30 minutes; large high-detail pieces may require several hours.

Summary

3D crystal engraving merges high-precision lasers, advanced optics, and 3D modeling software to create truly immersive keepsakes and functional prototypes. By understanding the key differences between 2D and 3D engraving, selecting the right crystal material, and optimizing your imagery, you can achieve stunning, permanent three-dimensional artworks.

.jpg)

Comments